Frequently Asked Questions

Cornell is taking a phased approach to researching and implementing Earth Source Heat. Learn more about the project, including frequently asked questions on several key topic areas.

Topic Areas:

- Phase I – Cornell University Borehole Observatory (CUBO)

- Phase II – Earth Source Heat (ESH)

- Drilling and Enhanced Geothermal System Safety

- Water safety

- Environmental Assessment

- Seismicity

- Additional Questions

Phase I – Cornell University Borehole Observatory (CUBO)

Why was CUBO necessary?

Earth Source Heat advanced for several years through acquisition and analysis of geophysical data, analysis of archived subsurface data from nearby oil and gas wells and engineering-economic analyses. While the results were promising, the point was reached at which the technical feasibility of ESH could not be further evaluated without measurements of deep subsurface rock conditions, using an exploratory borehole.

The borehole is not Intended for heat production, but rather to enable researchers to more accurately understand the geologic conditions. CUBO will also be used to deploy monitoring systems for ongoing use during future ESH project stages to support research and operations, and to ensure that the methods used do not create unacceptable risks or unintended impacts. Cornell is committed to evaluating and addressing both benefits and risks in a thorough and transparent manner in order to develop best practices for the campus, the greater community and for others who might implement this technology to sustainably meet their heating needs.

What is learned through this exploratory borehole project will be used to make decisions about whether to move forward with additional wells in which to test geothermal water flow and heat extraction. Download a flyer (PDF) to learn more about CUBO.

What is the design of CUBO?

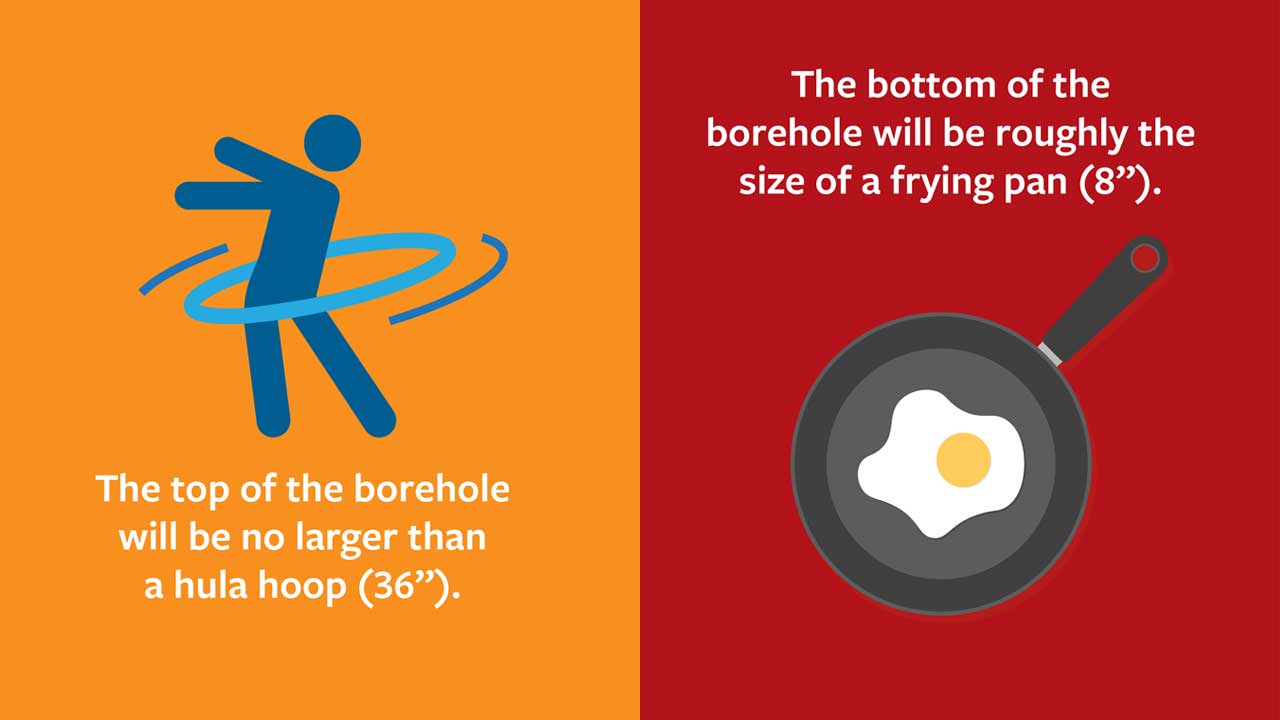

Using an electric drilling rig, the borehole reached a depth of 9,790 feet (1.85 miles). At the surface, the borehole is approximately 36 inches in diameter, progressively narrowing to about 8.5 inches in diameter at the deepest point. Regions in the subsurface which may contain fresh water or gas were sealed behind multiple layers of casing and cement. The longest casing extends 200 feet below the deepest rock unit that is known in this region to contain natural gas. The deepest portion of the borehole (greater than 7,808 feet or 1.47 miles below the surface) was left uncased to allow a variety of tests to be conducted within the rock layers of interest for geothermal development.

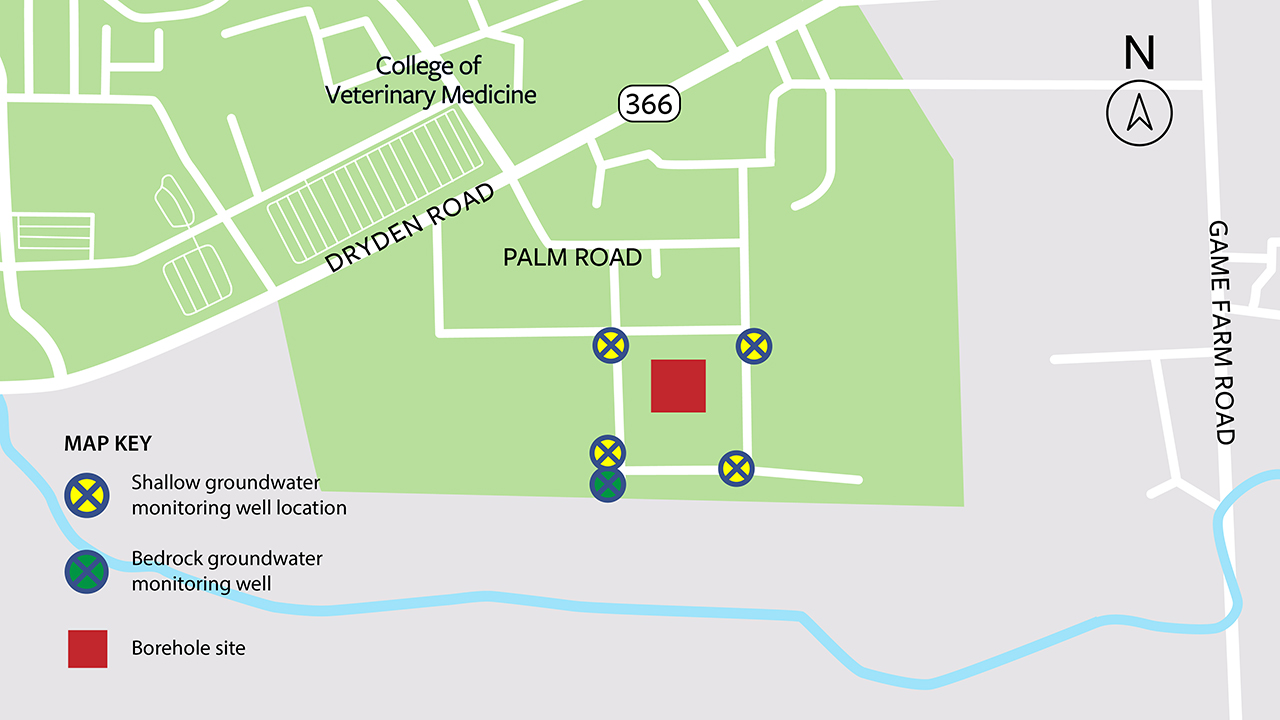

To ensure well casing integrity and safe operating conditions of CUBO, proper permitting and rigorous design reviews were completed. Water-monitoring wells and a network of seismometers were operational both prior to and during CUBO drilling to provide background data and to monitor conditions. While drilling is now complete and the site may appear inactive, essential research into the viability of Earth Source Heat continues.

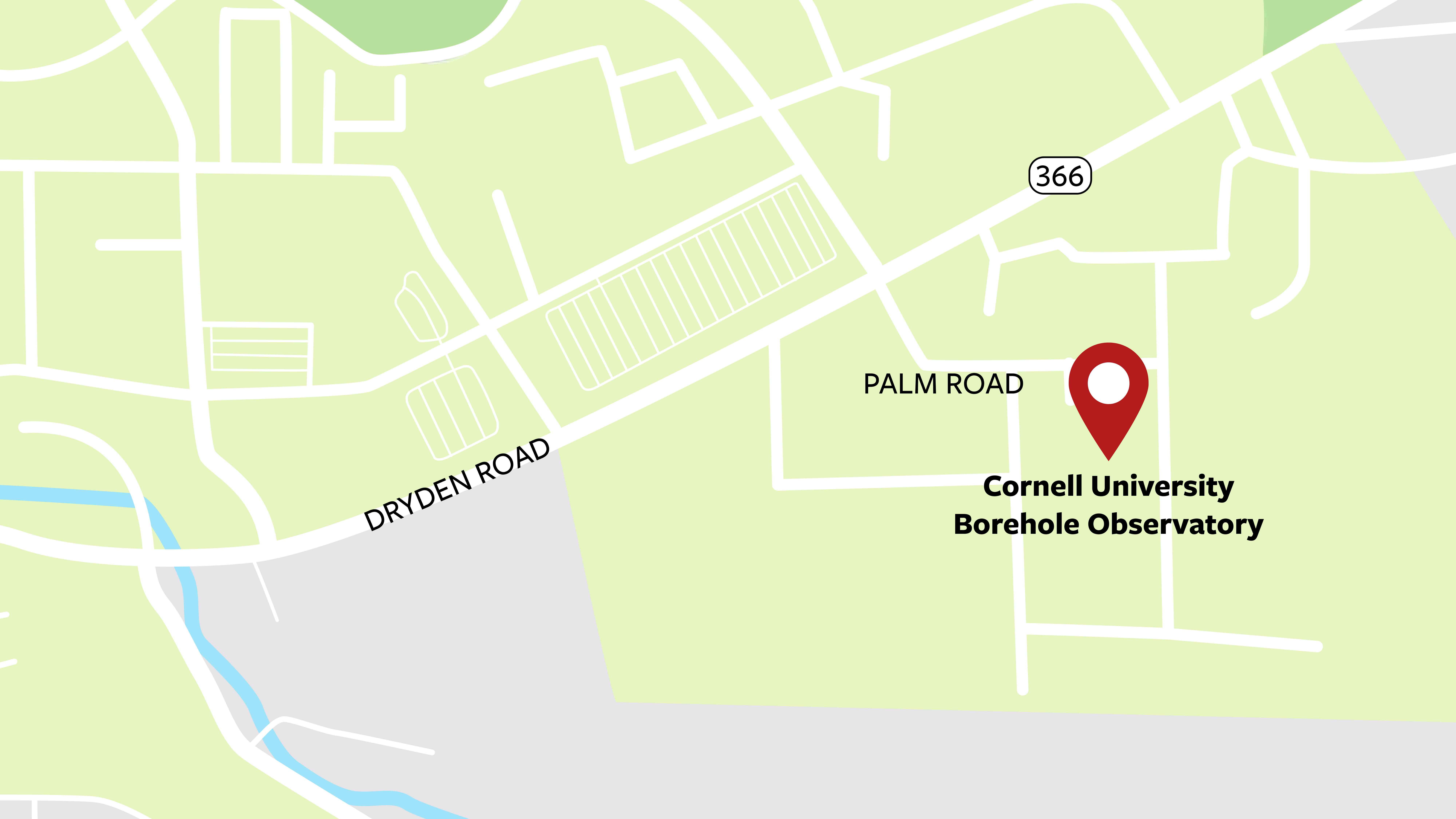

Where is CUBO located?

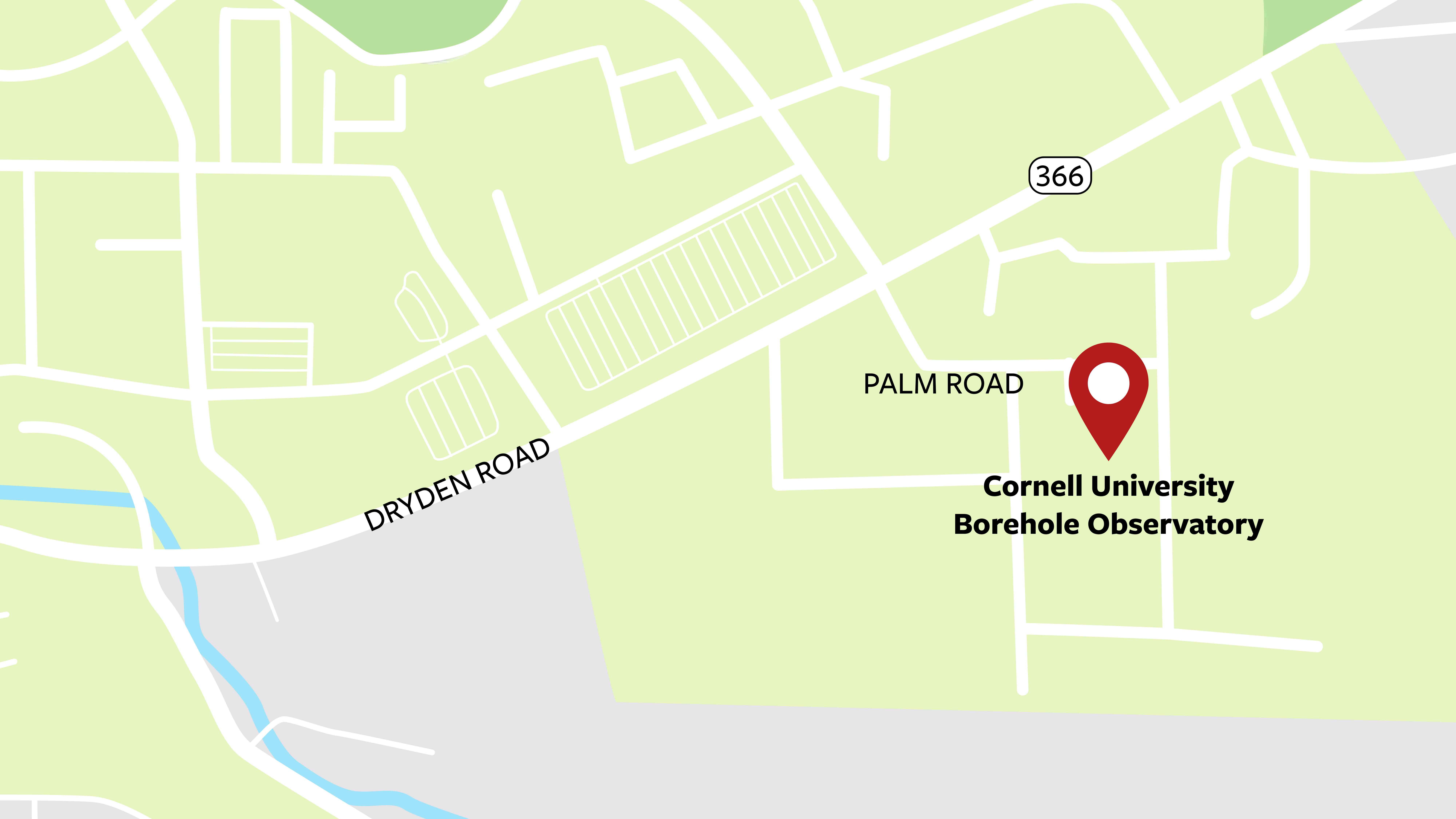

CUBO is located on Cornell-owned property near Palm Road in the Town of Ithaca. Drilling at the site did not disrupt plants, trees or sensitive ecosystems because the site was already an open gravel pad (a former parking lot). Additionally, electricity and water services were already available at this site, which eliminated the need for new disruptive construction to connect those resources. The area has been cleared and fenced in and a valve provides research access for future experiments.

What have we learned from CUBO so far?

Initial data from CUBO indicate that the temperature, rock type and permeability between 7,800- and 9,000-feet underground are consistent with initial hypotheses. The rock at that these depths have a temperature between 75 to 100 degrees Celsius and low intrinsic permeability (i.e., water does not easily flow through the rock). Three potentially suitable target zones for geothermal production were found, specifically vertical fracture zones orientated toward the northeast or horizontal weakness zones between sedimentary rock layers. Due to the low permeability of the bedrock, enhanced geothermal systems (EGS) technology – a current research focus of the U.S. Department of Energy – will be needed in order to efficiently utilize the heat within the rocks at these depths.

In addition to data for ESH, CUBO has helped researchers learn about past geologic and seismic events.

Phase II – Earth Source Heat

When would Cornell advance to an ESH demonstration project?

In collaboration with academic and industry experts from across the globe, the data from CUBO are being used to develop strategies for developing an Earth Source Heat system. Analysis of data from the exploratory borehole is being used to further characterize the subsurface hydrogeology and determine the nature and design of any future work to enhance the flow of water through the hot rock, if warranted.

If the data and analysis lead to a promising strategy for moving forward, and funding and other necessary permits are secured, the university would look to drill a demonstration well pair, possibly as soon as 2024.

How would the proposed ESH system work?

Earth Source Heat (ESH) is Cornell’s version of a geothermal system that would use the Earth’s constant, internal heat to warm the Ithaca campus. Well pairs would be drilled into deep sedimentary rock layers or into deeper crystalline “basement rock” where the internal heat of the Earth is much hotter than comfortable air temperatures. Water would be pumped down one well and flow through various fissures and fractures in the rock, called the heat reservoir, where it is naturally heated. The resulting hot water would then be drawn up into a second well and pumped to a heat exchange facility on the surface where it exchanges its thermal energy into a secondary closed-loop system which distributes hot water to Cornell’s campus buildings and facilities. After heat is extracted, the well water is recirculated via the injection well back into the deep rock to heat up again.

How will information gathered through CUBO inform ESH?

Cornell scientists continue to collect and analyze data from CUBO. This is analysis is crucial to make informed plans and decisions for a future ESH system, including identifying the best geologic zone and well design for sustained heat production.

Data analysis and modeling are being done to determine how many well pairs would be needed to heat the entire Ithaca campus using geothermal energy. To avoid overbuilding the system, faculty and engineers are exploring a hybrid system that would rely on another renewable energy option, such as bioenergy, to offset peak heating demand for extreme cold weather (about 20 days per year in Ithaca).

When would Cornell advance to an ESH demonstration project?

If the data and analysis lead to a promising strategy for moving forward, and funding and other necessary permits are secured, the university would look to drill a demonstration well pair, possibly sometime in 2024.

The university expects to develop the demonstration well pair at the site of CUBO and use well-known, modern drilling technologies to drill directionally underneath Cornell’s campus to maximize the surface area (and heat) available in the heat reservoir.

The initial demonstration well pair would serve a portion of the current campus heating load. If successful, Cornell would plan to transition the entire campus heating system to geothermal energy over the span of about 10 years.

Could the effectiveness of the heat reservoir reduce over time?

Data from CUBO are being analyzed and modeling using computer simulations will be performed to help predict how much surface area along fractures between wells would be needed to produce sustainable amounts of heat. A greater number of natural fractures create more surface area where water can absorb heat. In addition, greater distance between wells can result in larger surface area, but at the risk of having less flow connection between wells. With a large surface area, modest amounts of heat could be collected from many minute spaces, which can naturally be recharged by heat from the Earth. Conversely, with a small surface area, heat is extracted more quickly than it can naturally recharge. Researchers are working to design a system, based on the rock and fracture characteristics and subsurface conditions beneath Cornell, that can continue to produce heat for many years with a very slight temperature decline over time. Doing that requires finding and optimizing the amount of surface area along flow paths within the rocks.

Will the project be sized large enough to handle the full heat load for campus?

An initial demonstration well pair is estimated to serve a portion of the current campus heating load. If successful, the final build-out of Earth Source Heat would be optimally sized to deliver about 95% of campus’s annual heating demand. Rather than oversizing Earth Source Heat, another renewable energy system would be used to offset the infrequent peak heating days (+/- 20 per year).

Would Cornell need to build a new heat/power facility?

No. Cornell would retrofit the existing combined heat and power plant to heat campus using hot water from deep within the Earth, thereby eliminating the use of fossil fuels to heat campus. The only new facility would be a pump and heat exchanger facility, similar to but smaller than, the facility used for Lake Source Cooling. Heat storage tanks or similar supporting facilities could be included in the future, depending on the optimized final design.

Is the entire Ithaca campus currently converting from steam to hot water?

Cornell's current distribution system is a mixture of steam and hot water. To meet Cornell’s Climate Action Plan goals, all existing steam piping must be converted to hot water regardless of whether ESH is successful, as hot water is necessary to transfer renewable heat resources efficiently and economically. The conversion from steam to hot water is occurring incrementally to limit disruption, maintain redundancy and control expenses.

Will Earth Source Heat also be used to produce electricity?

The Earth Source Heat project is primarily interested in the direct use of geothermal resources for heating, which is very efficient, utilizing close to 100% of the extracted heat. In contrast, the process of converting geothermal heat to electricity would only use around 15% of the extracted heat and would not be an efficient use of the resources available in our area.

What will the production well site look like?

The production well site will be very similar to the CUBO site. The site would be restored after drilling, leaving only the very top of the wells and associated valves and piping visible at the surface. The location of the building to house the surface heat exchangers and pumps has not been determined. It may utilize an existing nearby campus facility or may require new construction.

How long could it take to create a full-scale Earth Source Heat system on the Ithaca campus?

If it is determined that ESH could safely and effectively advance, the next step would be to drill a separate demonstration well pair where water circulated through the wells would return to the surface as hot water and heat a portion of Cornell’s Ithaca campus. If successful, the university would move to a phased approach that would create a full-scale system capable of heating the entire Ithaca campus within the next 8 to 10 years.

Drilling and Enhanced Geothermal System Safety

What is an enhanced geothermal system?

Enhanced geothermal systems (EGS) allow geothermal heat to be utilized in areas where the subsurface has low permeability. Using this technology, an area of bedrock could be hydraulically stimulated to create interconnected pathways through which water can flow, in order for the slowly moving water to transport heat between a pair of wells. Tests conducted elsewhere show that permeability and connectivity of cracks and fractures in rocks similar to those beneath Cornell can be greatly increased in a safe and responsible manner so that they can act as the water pathways between wells. One demonstrated method of stimulation involves increasing the water pressure in a well by a small amount and sustaining that pressure over an extended period of time.

How would Earth Source Heat use EGS technology?

An initial demonstration well pair would be drilled into the hot sedimentary or metamorphic rock. Water would be pumped down the first injection well where rock would be hydraulically stimulated using relatively low water pressures. The stimulation would unclog flow pathways along existing fractures as well as connect fractures to create an interconnected and more permeable fracture network for fluid flow and heat exchange. The stimulation would develop a heat reservoir in which there is more surface area available to heat water and ensure strong connection between the wells. The rocks will naturally heat water as it flows from where it is injected in one well to where it is drawn up in a separate well. The geothermal water would then go through a heat exchanger where a secondary closed loop would carry a separate supply of fresh water (heated via the heat exchanger) throughout campus to heat buildings.

How is EGS technology different from oil and gas fracking?

Modern hydraulic fracturing for oil and gas production uses large volumes of water and other fluids under very high pressure to extract gas from fractures. It may even involve explosives, chemicals and proppants that can be harmful to the environment.

This is very different from Cornell’s plans for Earth Source Heat. Data from CUBO will allow researchers to identify the best ways to safely use EGS technology to stimulate fractures, including only those options that have low operational risk, low seismic risk and low environmental risk. Safety monitoring equipment and processes tested during CUBO will allow the water pressure to be quickly decreased if there is any indication that the stimulation might cause unintended seismic activity. No explosive techniques for creating permeability are under consideration for any phase of the Earth Source Heat project.

For more details, please watch: “Differences and similarities between Earth Source Heat and ‘Fracking’”

A.R. Ingraffea, Ph.D., P.E., Dist. Member ASCE

Dwight C. Baum Professor of Engineering Emeritus

Will the system release dangerous greenhouse gases or contaminate the subsurface through leakage of gas into the water?

The target depths for Earth Source Heat are at least three and a half times deeper than the depth of the Marcellus Shale and at least 450 feet below the Utica Shale beneath Ithaca. Of several target horizons investigated by CUBO, those numbers refer to the shallowest target, while other targets for ESH are much greater distances below those shales. Upward migration of injected fluids, or native fluids liberated by ESH well operations, is highly unlikely because of the target depths and because there are several thick, impermeable layers of rock between their investigation/production zones and freshwater zones.

Moreover, neither the Marcellus nor the Utica shale releases significant amounts of natural gas when crossed by a vertical wellbore – that is the reason that these rocks were not used to extract natural gas until the advent of horizontal drilling within them. While Cornell will have to drill vertically through these shales and other rock layers that bear gas elsewhere in New York state, comprehensive measures will be taken to minimize any release of gas from those layers during drilling and to seal off those zones using the casing/cementing approach described elsewhere in the FAQ. In the unlikely event that drilling does encounter a pocket of natural gas that requires discharge, it will be safely combusted on site using a flare system. If required, flaring would most likely last for a few hours or less. No gas pockets requiring flaring were encountered while CUBO was drilled.

Water Safety

How are wells constructed to protect groundwater and avoid other problems?

Valuable lessons have been learned from oil and natural gas production about best practices to promote long-term integrity of the well. Cornell is committed to using only high-quality cement, casings and other materials to minimize the probability of leaks.

The casing/cementing process is designed to minimize the probability of unwanted flow between freshwater zones and natural gas zones. The casing process keeps a well open, minimizes the probability of contamination of various rock strata and groundwater and, in combination with cement, shores up the wellbore itself. A steel tube is inserted into the borehole. Cement is pumped down the well and forced up the outside of the steel casing strings to form cement sheaths. Cornell plans to drill and case to depths of thousands of feet below the bottom of the freshwater zones to access hot rock that is far deeper than the Marcellus and Utica Shale layer.

How much water will be used and where will it come from?

Water for drilling operations for CUBO was used primarily to make drilling mud to cool the drill as it moved down into the Earth. This water mixed with dirt and rock cuttings and returned to the surface as mud, which was filtered out and injected back into the ground. The water came from Cornell’s campus water service through a water line adjacent to the site; no water was trucked in. The total water usage for drilling CUBO was less than one day of typical campus water use.

Should the project progress to installation and operation of a fully functional demonstration or production well pair, the water used will come from Cornell’s own water treatment plant, with total amount of water needed for the system for one year expected to be about 1% of what Cornell’s Ithaca campus typically uses in a single day. Should Earth Source Heat become operational for heating the Ithaca campus, water will be recirculated through cracks and crevices in the subsurface with minimal amounts of makeup water needed to replace any water that infiltrates into the deep bedrock. This makeup water will also be from Cornell’s own water service.

What measures will Cornell take to protect surface water resources?

For CUBO, drilling mud and water from well development and testing were contained in tanks or lined sumps to prevent infiltration into the soil. Any fluids that required disposal were treated as needed (for example, to remove sediment) prior to disposal at a treatment plant. In addition, Cornell required robust material storage, waste management and spill response plans from all contractors in order to prevent environmental impacts.

Ground and surface water risks are present with any drilling operation. Cornell’s plans minimized those risks, and a water testing program was implemented to monitor for any water impacts. Water was sampled to establish background conditions and then regularly re-sampled during drilling operations. Four groundwater wells 18-33’ deep, one bedrock well 207’ deep, and two sites in nearby Cascadilla Creek (both upstream and downstream of the CUBO project site) were sampled regularly. The swale between the CUBO site and Cascadilla Creek was actively monitored to verify that surface runoff did not occur during drilling operations.

Routine, frequent field monitoring was supplemented by robust lab analysis of samples taken before, midway through, and after drilling was completed. Experts from the NYS Water Resources Institute and Ithaca’s Water Treatment Plant reviewed the data. No drilling-related water quality impacts were observed during or after the project. Information on the sampling parameters and specific results will be available on Cornell’s Deep Geothermal Heat Research website.

Would any water that Cornell may inject into a demonstration/production well enter the local watershed?

No. Water injected into the well will not discharge into streams or freshwater aquifers. Freshwater is typically found only at shallow depths (up to several hundred feet), although some studies suggest it is possible there may be pockets of deep freshwater at depths approaching 1,000 feet (still well above the geothermal resources). The ESH demonstration wells will be cased and cemented into the ground for at least the first 7,500 feet below the surface, with multiple layers of steel casing and cement as required to meet groundwater protection standards.

How will the borehole casing prevent water contamination?

When the boreholes are drilled, they are lined with a steel pipe called “casing”. The casing is designed to minimize the possibility that there is any flow of liquids or gases between the well and the rock layers, including layers near the surface that contain groundwater (i.e., freshwater in the pore spaces of the rock). The casing also keeps the walls of the well solid so that rock doesn’t fall into and clog the drilled hole.

CUBO includes four layers of casing made of steel and cement. The casing has two layers, a steel tube inserted into the borehole, and cement pumped down the well and forced up the outside of the steel casing to form cement walls. There will also be casing at depths at which rocks rich in natural gas occur, including the Marcellus Shale and Utica Shale. This will avoid movement of natural gas into the well hole. The Marcellus and Utica shale layers are hundreds of feet above the target depth at which geothermal heat will be extracted.

How will the water be disposed of after use?

Some water used in the drilling and well field operation will be lost to the borehole. CUBO did not involve active water circulation, but for a future production well pair, water would be pumped out of the production well and the same water would be injected into a return well. In this case, there is typically no excess water for discharge, and used water is recirculated. If some water does need disposal, it will be contained, tested and disposed of through an appropriately licensed disposal facility, with oversight by Cornell Environmental Health and Safety.

Will chemicals be injected into the well?

During the lifetime of CUBO and any possible follow-on well pairs, it is likely that some chemicals other than water will be needed during the various phases of drilling, casing, cementing, possible stimulation, heat production, maintenance and eventual abandonment. However, Cornell is committed to using only environmentally safe materials, to providing complete transparency about any planned chemical additives, to incorporating a safety review of those substances in the environmental assessment, and to incorporating appropriate testing and monitoring into the plan as needed to minimize any potential risk.

Could the water flow in a production well decrease over time?

Research teams are studying the geochemistry of the rocks and working to design a system where water flow can be maintained without breakdown or lessening in quality.

Environmental Assessment

Will an environmental assessment of the impact of drilling a demonstration well pair be completed before beginning construction?

Yes. The proper permitting and required studies were completed prior to the drilling of CUBO and will also be completed prior to drilling any demonstration or production well pairs. The New York State Department of Environmental Conservation (NYSDEC) would be the agency responsible for overseeing well and drilling permits and meeting State Environmental Quality Review Act (SEQR) and other state requirements.

For CUBO, the NYSDEC stratigraphic well permit application included a streamlined environmental assessment process. Future demonstration well pairs will include a review of the broad range of environmental, social and economic impacts typical of a comprehensive SEQR assessment. Additionally, should development proceed beyond the CUBO project, the local municipality would have oversight through their Site Plan Approval process, which also requires a SEQR assessment.

Seismicity

Is the Earth Source Heat demonstration project likely to cause felt earthquakes?

During CUBO, researchers sought to better understand the local subsurface systems, including studying the geology, hydrology and natural seismicity using existing wells and surface instruments. This included analysis of the “background” rate of small earthquakes resulting from natural forces and to help identify the location of existing bedrock faults. Understanding these factors – along with designing an ESH system that uses carefully selected pressures, volumes of water and a sophisticated seismic monitoring system – will allow researchers and engineers to reduce several risk factors.

A state-of-the-art seismic monitoring system was developed to provide a reliable and data-driven method to track seismic activity (whether related to the project or not) during all phases of CUBO and ESH. The system looked at frequency, magnitude and location of events that occur anywhere in the monitoring network. No seismic impacts were anticipated and nothing unusual was seen during the CUBO drilling process (Information on the network and specific results is available on Cornell’s Deep Geothermal Heat Research website).

Such data will allow Cornell to carefully plan and control any future stimulation actions, thus ensuring that the development of geothermal resources is accomplished as safely as possible. In later phases, additional safety measures such as a traffic light system will be established, based on international standards, to ensure that geothermal practices only generate very small microseismicity well below the level that can be felt by humans.

Should the project advance to subsequent phases, very small seismic events could be generated, particularly during stimulation when pressurized water will be moving through the deep bedrock. Typically, earthquakes in this situation have magnitudes less than zero, far too small to be felt or cause damage, though there is a remote chance of seismic activity large enough to be felt at the surface. The monitoring protocol using the network established during CUBO would be used to rapidly detect any increases in seismicity so that water pressure can be adjusted as needed. Such a system will build on considerable experience with microseismicity in the geothermal industry.

Can stimulated fractures grow in an uncontrolled way?

Friction, imposed by the weight of rock, will diminish the probability of the stimulated natural fractures growing and extending in an uncontrolled way. Only where water pressure is substantially increased by injection at a well will friction be reduced enough to cause fracture to propogate. As has been recently reported, long-term and continuous forced-pressure water disposal in some areas of the country have created felt seismic events. No such water disposal activities will be part of our system.

Additional Questions

What is the potential greenhouse gas impact of Earth Source Heat on the campus and local area?

Heating accounts for 30% of campus greenhouse gas emissions and remains the biggest hurdle to Cornell becoming carbon neutral by 2035. Earth Source Heat would enable Cornell to move beyond fossil fuels and would also reduce Tompkins County greenhouse gas emissions by about 7%. In the Northeast, 20-40% of carbon emissions come from heating. If this technology can be advanced, it could rapidly reduce emissions on a large scale.

ESH also has the lowest electrical demand of any renewable heating option, freeing up electricity for meeting local and state renewable electricity demands. It would provide a baseload heating solution that can be integrated with other renewable options like biomass, heat pumps or stored solar thermal.

Additionally, Cornell can use existing infrastructure that heats its buildings, reducing the need for new infrastructure or wasting old systems.

Will the project adversely affect local property values or neighboring ground heat potential?

No. All wells will be located on Cornell property and within a reasonable distance from local residential areas. As such, adverse effects to local property values or ground heat potential in neighboring areas are not anticipated.

What does Cornell expect for broader impact of this technology?

If deemed viable, Earth Source Heat may prove to be a critical renewable asset for decarbonizing our society. Cornell’s intention is to demonstrate the viability of geothermal heating for cold climates around the world, including in New York state. Should the technology be successfully demonstrated at scale, the goal would be for broad development to continue through public and private entities.

Will there be educational outreach associated with the ESH project?

Cornell is working with community partners to create multi-faceted educational materials intended for a variety of age groups. In cooperation with the Outreach and Teacher Education experts of Paleontological Research Institution and the Online Education and Documentary Film experts of PhotoSynthesis Productions, Cornell is developing materials intended for curious adults and children, and teachers. General information as well as materials for K-16 teachers can be found on the Deep Geothermal Heat Research website.

Is the site open for the public to explore and learn more about this project?

The drilling rig and machinery has been removed from the site. When visiting CUBO, be sure to remain outside of the fenced-in area. To have someone from the Earth Source Heat team talk with your group, complete the form on the Contact Us page

Will there be public access to the data generated by this project?

Data generated by the Earth Source Heat project will be available for public access. Visit the Deep Geothermal Heat Research website for additional information.

Why is Cornell uniquely suited to take on this project?

While many in Ithaca and the surrounding communities are supportive of clean energy development, as evident in the Tompkins County Energy Roadmap, Cornell understands that this type of project has not been attempted in the region before, leading to many questions about its feasibility and scope. As an academic institution with deep faculty expertise in emerging energy technology, seismicity, geology and the environment, Cornell is uniquely suited to explore Earth Source Heat. Even if ESH is not able to be fully implemented, valuable knowledge will still be gained about rock formations beneath campus as well as possible system designs that could be beneficial to other institutions, businesses and communities considering this technology.

Where have similar geothermal projects been implemented?

The first enhanced geothermal system (EGS) wells were completed in 1977 and 1986 to demonstrate their potential, but only recently have projects begun to develop EGS for long-term, large-scale energy and heating use. Cornell is among the first organizations to receive a Funding Opportunity Announcement from the U.S. Department of Energy to develop EGS heating. However, Fervo Energy has been developing EGS since its inception in 2017 and has since successfully built two geothermal plants – one in Utah and one in Nevada – which will reliably generate energy for surrounding states and their electric utility companies by 2026.

Phase I – Cornell University Borehole Observatory (CUBO)

Why was CUBO necessary?

Earth Source Heat advanced for several years through acquisition and analysis of geophysical data, analysis of archived subsurface data from nearby oil and gas wells and engineering-economic analyses. While the results were promising, the point was reached at which the technical feasibility of ESH could not be further evaluated without measurements of deep subsurface rock conditions, using an exploratory borehole.

The borehole is not Intended for heat production, but rather to enable researchers to more accurately understand the geologic conditions. CUBO will also be used to deploy monitoring systems for ongoing use during future ESH project stages to support research and operations, and to ensure that the methods used do not create unacceptable risks or unintended impacts. Cornell is committed to evaluating and addressing both benefits and risks in a thorough and transparent manner in order to develop best practices for the campus, the greater community and for others who might implement this technology to sustainably meet their heating needs.

What is learned through this exploratory borehole project will be used to make decisions about whether to move forward with additional wells in which to test geothermal water flow and heat extraction. Download a flyer (PDF) to learn more about CUBO.

What is the design of CUBO?

Using an electric drilling rig, the borehole reached a depth of 9,790 feet (1.85 miles). At the surface, the borehole is approximately 36 inches in diameter, progressively narrowing to about 8.5 inches in diameter at the deepest point. Regions in the subsurface which may contain fresh water or gas were sealed behind multiple layers of casing and cement. The longest casing extends 200 feet below the deepest rock unit that is known in this region to contain natural gas. The deepest portion of the borehole (greater than 7,808 feet or 1.47 miles below the surface) was left uncased to allow a variety of tests to be conducted within the rock layers of interest for geothermal development.

To ensure well casing integrity and safe operating conditions of CUBO, proper permitting and rigorous design reviews were completed. Water-monitoring wells and a network of seismometers were operational both prior to and during CUBO drilling to provide background data and to monitor conditions. While drilling is now complete and the site may appear inactive, essential research into the viability of Earth Source Heat continues.

Where is CUBO located?

CUBO is located on Cornell-owned property near Palm Road in the Town of Ithaca. Drilling at the site did not disrupt plants, trees or sensitive ecosystems because the site was already an open gravel pad (a former parking lot). Additionally, electricity and water services were already available at this site, which eliminated the need for new disruptive construction to connect those resources. The area has been cleared and fenced in and a valve provides research access for future experiments.

What have we learned from CUBO so far?

Initial data from CUBO indicate that the temperature, rock type and permeability between 7,800- and 9,000-feet underground are consistent with initial hypotheses. The rock at that these depths have a temperature between 75 to 100 degrees Celsius and low intrinsic permeability (i.e., water does not easily flow through the rock). Three potentially suitable target zones for geothermal production were found, specifically vertical fracture zones orientated toward the northeast or horizontal weakness zones between sedimentary rock layers. Due to the low permeability of the bedrock, enhanced geothermal systems (EGS) technology – a current research focus of the U.S. Department of Energy – will be needed in order to efficiently utilize the heat within the rocks at these depths.

In addition to data for ESH, CUBO has helped researchers learn about past geologic and seismic events.

Phase II – Earth Source Heat

When would Cornell advance to an ESH demonstration project?

In collaboration with academic and industry experts from across the globe, the data from CUBO are being used to develop strategies for developing an Earth Source Heat system. Analysis of data from the exploratory borehole is being used to further characterize the subsurface hydrogeology and determine the nature and design of any future work to enhance the flow of water through the hot rock, if warranted.

If the data and analysis lead to a promising strategy for moving forward, and funding and other necessary permits are secured, the university would look to drill a demonstration well pair, possibly as soon as 2024.

How would the proposed ESH system work?

Earth Source Heat (ESH) is Cornell’s version of a geothermal system that would use the Earth’s constant, internal heat to warm the Ithaca campus. Well pairs would be drilled into deep sedimentary rock layers or into deeper crystalline “basement rock” where the internal heat of the Earth is much hotter than comfortable air temperatures. Water would be pumped down one well and flow through various fissures and fractures in the rock, called the heat reservoir, where it is naturally heated. The resulting hot water would then be drawn up into a second well and pumped to a heat exchange facility on the surface where it exchanges its thermal energy into a secondary closed-loop system which distributes hot water to Cornell’s campus buildings and facilities. After heat is extracted, the well water is recirculated via the injection well back into the deep rock to heat up again.

How will information gathered through CUBO inform ESH?

Cornell scientists continue to collect and analyze data from CUBO. This is analysis is crucial to make informed plans and decisions for a future ESH system, including identifying the best geologic zone and well design for sustained heat production.

Data analysis and modeling are being done to determine how many well pairs would be needed to heat the entire Ithaca campus using geothermal energy. To avoid overbuilding the system, faculty and engineers are exploring a hybrid system that would rely on another renewable energy option, such as bioenergy, to offset peak heating demand for extreme cold weather (about 20 days per year in Ithaca).

When would Cornell advance to an ESH demonstration project?

If the data and analysis lead to a promising strategy for moving forward, and funding and other necessary permits are secured, the university would look to drill a demonstration well pair, possibly sometime in 2024.

The university expects to develop the demonstration well pair at the site of CUBO and use well-known, modern drilling technologies to drill directionally underneath Cornell’s campus to maximize the surface area (and heat) available in the heat reservoir.

The initial demonstration well pair would serve a portion of the current campus heating load. If successful, Cornell would plan to transition the entire campus heating system to geothermal energy over the span of about 10 years.

Could the effectiveness of the heat reservoir reduce over time?

Data from CUBO are being analyzed and modeling using computer simulations will be performed to help predict how much surface area along fractures between wells would be needed to produce sustainable amounts of heat. A greater number of natural fractures create more surface area where water can absorb heat. In addition, greater distance between wells can result in larger surface area, but at the risk of having less flow connection between wells. With a large surface area, modest amounts of heat could be collected from many minute spaces, which can naturally be recharged by heat from the Earth. Conversely, with a small surface area, heat is extracted more quickly than it can naturally recharge. Researchers are working to design a system, based on the rock and fracture characteristics and subsurface conditions beneath Cornell, that can continue to produce heat for many years with a very slight temperature decline over time. Doing that requires finding and optimizing the amount of surface area along flow paths within the rocks.

Will the project be sized large enough to handle the full heat load for campus?

An initial demonstration well pair is estimated to serve a portion of the current campus heating load. If successful, the final build-out of Earth Source Heat would be optimally sized to deliver about 95% of campus’s annual heating demand. Rather than oversizing Earth Source Heat, another renewable energy system would be used to offset the infrequent peak heating days (+/- 20 per year).

Would Cornell need to build a new heat/power facility?

No. Cornell would retrofit the existing combined heat and power plant to heat campus using hot water from deep within the Earth, thereby eliminating the use of fossil fuels to heat campus. The only new facility would be a pump and heat exchanger facility, similar to but smaller than, the facility used for Lake Source Cooling. Heat storage tanks or similar supporting facilities could be included in the future, depending on the optimized final design.

Is the entire Ithaca campus currently converting from steam to hot water?

Cornell's current distribution system is a mixture of steam and hot water. To meet Cornell’s Climate Action Plan goals, all existing steam piping must be converted to hot water regardless of whether ESH is successful, as hot water is necessary to transfer renewable heat resources efficiently and economically. The conversion from steam to hot water is occurring incrementally to limit disruption, maintain redundancy and control expenses.

Will Earth Source Heat also be used to produce electricity?

The Earth Source Heat project is primarily interested in the direct use of geothermal resources for heating, which is very efficient, utilizing close to 100% of the extracted heat. In contrast, the process of converting geothermal heat to electricity would only use around 15% of the extracted heat and would not be an efficient use of the resources available in our area.

What will the production well site look like?

The production well site will be very similar to the CUBO site. The site would be restored after drilling, leaving only the very top of the wells and associated valves and piping visible at the surface. The location of the building to house the surface heat exchangers and pumps has not been determined. It may utilize an existing nearby campus facility or may require new construction.

How long could it take to create a full-scale Earth Source Heat system on the Ithaca campus?

If it is determined that ESH could safely and effectively advance, the next step would be to drill a separate demonstration well pair where water circulated through the wells would return to the surface as hot water and heat a portion of Cornell’s Ithaca campus. If successful, the university would move to a phased approach that would create a full-scale system capable of heating the entire Ithaca campus within the next 8 to 10 years.

Drilling and Enhanced Geothermal System Safety

What is an enhanced geothermal system?

Enhanced geothermal systems (EGS) allow geothermal heat to be utilized in areas where the subsurface has low permeability. Using this technology, an area of bedrock could be hydraulically stimulated to create interconnected pathways through which water can flow, in order for the slowly moving water to transport heat between a pair of wells. Tests conducted elsewhere show that permeability and connectivity of cracks and fractures in rocks similar to those beneath Cornell can be greatly increased in a safe and responsible manner so that they can act as the water pathways between wells. One demonstrated method of stimulation involves increasing the water pressure in a well by a small amount and sustaining that pressure over an extended period of time.

How would Earth Source Heat use EGS technology?

An initial demonstration well pair would be drilled into the hot sedimentary or metamorphic rock. Water would be pumped down the first injection well where rock would be hydraulically stimulated using relatively low water pressures. The stimulation would unclog flow pathways along existing fractures as well as connect fractures to create an interconnected and more permeable fracture network for fluid flow and heat exchange. The stimulation would develop a heat reservoir in which there is more surface area available to heat water and ensure strong connection between the wells. The rocks will naturally heat water as it flows from where it is injected in one well to where it is drawn up in a separate well. The geothermal water would then go through a heat exchanger where a secondary closed loop would carry a separate supply of fresh water (heated via the heat exchanger) throughout campus to heat buildings.

How is EGS technology different from oil and gas fracking?

Modern hydraulic fracturing for oil and gas production uses large volumes of water and other fluids under very high pressure to extract gas from fractures. It may even involve explosives, chemicals and proppants that can be harmful to the environment.

This is very different from Cornell’s plans for Earth Source Heat. Data from CUBO will allow researchers to identify the best ways to safely use EGS technology to stimulate fractures, including only those options that have low operational risk, low seismic risk and low environmental risk. Safety monitoring equipment and processes tested during CUBO will allow the water pressure to be quickly decreased if there is any indication that the stimulation might cause unintended seismic activity. No explosive techniques for creating permeability are under consideration for any phase of the Earth Source Heat project.

For more details, please watch: “Differences and similarities between Earth Source Heat and ‘Fracking’”

A.R. Ingraffea, Ph.D., P.E., Dist. Member ASCE

Dwight C. Baum Professor of Engineering Emeritus

Will the system release dangerous greenhouse gases or contaminate the subsurface through leakage of gas into the water?

The target depths for Earth Source Heat are at least three and a half times deeper than the depth of the Marcellus Shale and at least 450 feet below the Utica Shale beneath Ithaca. Of several target horizons investigated by CUBO, those numbers refer to the shallowest target, while other targets for ESH are much greater distances below those shales. Upward migration of injected fluids, or native fluids liberated by ESH well operations, is highly unlikely because of the target depths and because there are several thick, impermeable layers of rock between their investigation/production zones and freshwater zones.

Moreover, neither the Marcellus nor the Utica shale releases significant amounts of natural gas when crossed by a vertical wellbore – that is the reason that these rocks were not used to extract natural gas until the advent of horizontal drilling within them. While Cornell will have to drill vertically through these shales and other rock layers that bear gas elsewhere in New York state, comprehensive measures will be taken to minimize any release of gas from those layers during drilling and to seal off those zones using the casing/cementing approach described elsewhere in the FAQ. In the unlikely event that drilling does encounter a pocket of natural gas that requires discharge, it will be safely combusted on site using a flare system. If required, flaring would most likely last for a few hours or less. No gas pockets requiring flaring were encountered while CUBO was drilled.

Water Safety

How are wells constructed to protect groundwater and avoid other problems?

Valuable lessons have been learned from oil and natural gas production about best practices to promote long-term integrity of the well. Cornell is committed to using only high-quality cement, casings and other materials to minimize the probability of leaks.

The casing/cementing process is designed to minimize the probability of unwanted flow between freshwater zones and natural gas zones. The casing process keeps a well open, minimizes the probability of contamination of various rock strata and groundwater and, in combination with cement, shores up the wellbore itself. A steel tube is inserted into the borehole. Cement is pumped down the well and forced up the outside of the steel casing strings to form cement sheaths. Cornell plans to drill and case to depths of thousands of feet below the bottom of the freshwater zones to access hot rock that is far deeper than the Marcellus and Utica Shale layer.

How much water will be used and where will it come from?

Water for drilling operations for CUBO was used primarily to make drilling mud to cool the drill as it moved down into the Earth. This water mixed with dirt and rock cuttings and returned to the surface as mud, which was filtered out and injected back into the ground. The water came from Cornell’s campus water service through a water line adjacent to the site; no water was trucked in. The total water usage for drilling CUBO was less than one day of typical campus water use.

Should the project progress to installation and operation of a fully functional demonstration or production well pair, the water used will come from Cornell’s own water treatment plant, with total amount of water needed for the system for one year expected to be about 1% of what Cornell’s Ithaca campus typically uses in a single day. Should Earth Source Heat become operational for heating the Ithaca campus, water will be recirculated through cracks and crevices in the subsurface with minimal amounts of makeup water needed to replace any water that infiltrates into the deep bedrock. This makeup water will also be from Cornell’s own water service.

What measures will Cornell take to protect surface water resources?

For CUBO, drilling mud and water from well development and testing were contained in tanks or lined sumps to prevent infiltration into the soil. Any fluids that required disposal were treated as needed (for example, to remove sediment) prior to disposal at a treatment plant. In addition, Cornell required robust material storage, waste management and spill response plans from all contractors in order to prevent environmental impacts.

Ground and surface water risks are present with any drilling operation. Cornell’s plans minimized those risks, and a water testing program was implemented to monitor for any water impacts. Water was sampled to establish background conditions and then regularly re-sampled during drilling operations. Four groundwater wells 18-33’ deep, one bedrock well 207’ deep, and two sites in nearby Cascadilla Creek (both upstream and downstream of the CUBO project site) were sampled regularly. The swale between the CUBO site and Cascadilla Creek was actively monitored to verify that surface runoff did not occur during drilling operations.

Routine, frequent field monitoring was supplemented by robust lab analysis of samples taken before, midway through, and after drilling was completed. Experts from the NYS Water Resources Institute and Ithaca’s Water Treatment Plant reviewed the data. No drilling-related water quality impacts were observed during or after the project. Information on the sampling parameters and specific results will be available on Cornell’s Deep Geothermal Heat Research website.

Would any water that Cornell may inject into a demonstration/production well enter the local watershed?

No. Water injected into the well will not discharge into streams or freshwater aquifers. Freshwater is typically found only at shallow depths (up to several hundred feet), although some studies suggest it is possible there may be pockets of deep freshwater at depths approaching 1,000 feet (still well above the geothermal resources). The ESH demonstration wells will be cased and cemented into the ground for at least the first 7,500 feet below the surface, with multiple layers of steel casing and cement as required to meet groundwater protection standards.

How will the borehole casing prevent water contamination?

When the boreholes are drilled, they are lined with a steel pipe called “casing”. The casing is designed to minimize the possibility that there is any flow of liquids or gases between the well and the rock layers, including layers near the surface that contain groundwater (i.e., freshwater in the pore spaces of the rock). The casing also keeps the walls of the well solid so that rock doesn’t fall into and clog the drilled hole.

CUBO includes four layers of casing made of steel and cement. The casing has two layers, a steel tube inserted into the borehole, and cement pumped down the well and forced up the outside of the steel casing to form cement walls. There will also be casing at depths at which rocks rich in natural gas occur, including the Marcellus Shale and Utica Shale. This will avoid movement of natural gas into the well hole. The Marcellus and Utica shale layers are hundreds of feet above the target depth at which geothermal heat will be extracted.

How will the water be disposed of after use?

Some water used in the drilling and well field operation will be lost to the borehole. CUBO did not involve active water circulation, but for a future production well pair, water would be pumped out of the production well and the same water would be injected into a return well. In this case, there is typically no excess water for discharge, and used water is recirculated. If some water does need disposal, it will be contained, tested and disposed of through an appropriately licensed disposal facility, with oversight by Cornell Environmental Health and Safety.

Will chemicals be injected into the well?

During the lifetime of CUBO and any possible follow-on well pairs, it is likely that some chemicals other than water will be needed during the various phases of drilling, casing, cementing, possible stimulation, heat production, maintenance and eventual abandonment. However, Cornell is committed to using only environmentally safe materials, to providing complete transparency about any planned chemical additives, to incorporating a safety review of those substances in the environmental assessment, and to incorporating appropriate testing and monitoring into the plan as needed to minimize any potential risk.

Could the water flow in a production well decrease over time?

Research teams are studying the geochemistry of the rocks and working to design a system where water flow can be maintained without breakdown or lessening in quality.

Environmental Assessment

Will an environmental assessment of the impact of drilling a demonstration well pair be completed before beginning construction?

Yes. The proper permitting and required studies were completed prior to the drilling of CUBO and will also be completed prior to drilling any demonstration or production well pairs. The New York State Department of Environmental Conservation (NYSDEC) would be the agency responsible for overseeing well and drilling permits and meeting State Environmental Quality Review Act (SEQR) and other state requirements.

For CUBO, the NYSDEC stratigraphic well permit application included a streamlined environmental assessment process. Future demonstration well pairs will include a review of the broad range of environmental, social and economic impacts typical of a comprehensive SEQR assessment. Additionally, should development proceed beyond the CUBO project, the local municipality would have oversight through their Site Plan Approval process, which also requires a SEQR assessment.

Seismicity

Is the Earth Source Heat demonstration project likely to cause felt earthquakes?

During CUBO, researchers sought to better understand the local subsurface systems, including studying the geology, hydrology and natural seismicity using existing wells and surface instruments. This included analysis of the “background” rate of small earthquakes resulting from natural forces and to help identify the location of existing bedrock faults. Understanding these factors – along with designing an ESH system that uses carefully selected pressures, volumes of water and a sophisticated seismic monitoring system – will allow researchers and engineers to reduce several risk factors.

A state-of-the-art seismic monitoring system was developed to provide a reliable and data-driven method to track seismic activity (whether related to the project or not) during all phases of CUBO and ESH. The system looked at frequency, magnitude and location of events that occur anywhere in the monitoring network. No seismic impacts were anticipated and nothing unusual was seen during the CUBO drilling process (Information on the network and specific results is available on Cornell’s Deep Geothermal Heat Research website).

Such data will allow Cornell to carefully plan and control any future stimulation actions, thus ensuring that the development of geothermal resources is accomplished as safely as possible. In later phases, additional safety measures such as a traffic light system will be established, based on international standards, to ensure that geothermal practices only generate very small microseismicity well below the level that can be felt by humans.

Should the project advance to subsequent phases, very small seismic events could be generated, particularly during stimulation when pressurized water will be moving through the deep bedrock. Typically, earthquakes in this situation have magnitudes less than zero, far too small to be felt or cause damage, though there is a remote chance of seismic activity large enough to be felt at the surface. The monitoring protocol using the network established during CUBO would be used to rapidly detect any increases in seismicity so that water pressure can be adjusted as needed. Such a system will build on considerable experience with microseismicity in the geothermal industry.

Can stimulated fractures grow in an uncontrolled way?

Friction, imposed by the weight of rock, will diminish the probability of the stimulated natural fractures growing and extending in an uncontrolled way. Only where water pressure is substantially increased by injection at a well will friction be reduced enough to cause fracture to propogate. As has been recently reported, long-term and continuous forced-pressure water disposal in some areas of the country have created felt seismic events. No such water disposal activities will be part of our system.

Additional Questions

What is the potential greenhouse gas impact of Earth Source Heat on the campus and local area?

Heating accounts for 30% of campus greenhouse gas emissions and remains the biggest hurdle to Cornell becoming carbon neutral by 2035. Earth Source Heat would enable Cornell to move beyond fossil fuels and would also reduce Tompkins County greenhouse gas emissions by about 7%. In the Northeast, 20-40% of carbon emissions come from heating. If this technology can be advanced, it could rapidly reduce emissions on a large scale.

ESH also has the lowest electrical demand of any renewable heating option, freeing up electricity for meeting local and state renewable electricity demands. It would provide a baseload heating solution that can be integrated with other renewable options like biomass, heat pumps or stored solar thermal.

Additionally, Cornell can use existing infrastructure that heats its buildings, reducing the need for new infrastructure or wasting old systems.

Will the project adversely affect local property values or neighboring ground heat potential?

No. All wells will be located on Cornell property and within a reasonable distance from local residential areas. As such, adverse effects to local property values or ground heat potential in neighboring areas are not anticipated.

What does Cornell expect for broader impact of this technology?

If deemed viable, Earth Source Heat may prove to be a critical renewable asset for decarbonizing our society. Cornell’s intention is to demonstrate the viability of geothermal heating for cold climates around the world, including in New York state. Should the technology be successfully demonstrated at scale, the goal would be for broad development to continue through public and private entities.

Will there be educational outreach associated with the ESH project?

Cornell is working with community partners to create multi-faceted educational materials intended for a variety of age groups. In cooperation with the Outreach and Teacher Education experts of Paleontological Research Institution and the Online Education and Documentary Film experts of PhotoSynthesis Productions, Cornell is developing materials intended for curious adults and children, and teachers. General information as well as materials for K-16 teachers can be found on the Deep Geothermal Heat Research website.

Is the site open for the public to explore and learn more about this project?

The drilling rig and machinery has been removed from the site. When visiting CUBO, be sure to remain outside of the fenced-in area. To have someone from the Earth Source Heat team talk with your group, complete the form on the Contact Us page

Will there be public access to the data generated by this project?

Data generated by the Earth Source Heat project will be available for public access. Visit the Deep Geothermal Heat Research website for additional information.

Why is Cornell uniquely suited to take on this project?

While many in Ithaca and the surrounding communities are supportive of clean energy development, as evident in the Tompkins County Energy Roadmap, Cornell understands that this type of project has not been attempted in the region before, leading to many questions about its feasibility and scope. As an academic institution with deep faculty expertise in emerging energy technology, seismicity, geology and the environment, Cornell is uniquely suited to explore Earth Source Heat. Even if ESH is not able to be fully implemented, valuable knowledge will still be gained about rock formations beneath campus as well as possible system designs that could be beneficial to other institutions, businesses and communities considering this technology.

Where have similar geothermal projects been implemented?

The first enhanced geothermal system (EGS) wells were completed in 1977 and 1986 to demonstrate their potential, but only recently have projects begun to develop EGS for long-term, large-scale energy and heating use. Cornell is among the first organizations to receive a Funding Opportunity Announcement from the U.S. Department of Energy to develop EGS heating. However, Fervo Energy has been developing EGS since its inception in 2017 and has since successfully built two geothermal plants – one in Utah and one in Nevada – which will reliably generate energy for surrounding states and their electric utility companies by 2026.